There is a better way to pump the effluent, overflow and other collected “dirty” water around your plant. Vertical slurry pumps from Schurco can solve many issues that arise when pumping effluent. Above-ground sumps are difficult to maintain, and cause headaches when they run dry and your pump begins to inevitably cavitate and destroy itself. Schurco proudly offers an answer to these and other problems through the use of their low-maintenance and robustly designed vertical cantilever slurry pumps, their V Series model.

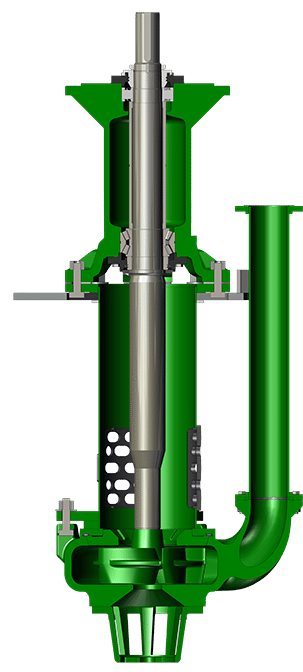

The V Series is unique from other vertical pumps. It is fully cantilevered by design, and does not require lower bearings or external sealing or cooling water. These pumps can also run completely dry with no adverse consequences to the equipment in what is called “snore” mode. Cavitation is a thing of the past!

Chief Design Features:

- NO SUBMERGED BEARINGS; eliminates submerged bearings, packing, lip seals, and mechanical seals

- NO SHAFT SEAL; due to the unique double suction impellers fluid flow enters the top as well as the bottom, and eliminates the requirement for a shaft seal

- SAFE TO RUN DRY; can run completely dry without adverse consequences

- ROBUST BEARING ASSEMBLY; the maintenance-friendly bearing assembly has heavy-duty roller bearings, robust bearing housings, and a massive shaft.

- HIGHLY ABRASIVE RESISTANT WETTED PARTS; metal construction pumps have a heavy-walled abrasive-resistant chrome alloy casing. Rubber construction pumps have a molded rubber casing adhered to sturdy metal sub-structures.

The technology behind these pumps is purposefully simple: oversized bearings, oversized shafts, thick chrome-iron or rubber-lined castings, and a solid integrated platform. This pump is robust where it counts, even including a cast discharge neck on the pump casings themselves, unlike previous generations of pumps which used pipe elbows. Large vane passages on the impeller means large chunks of rock or trash can easily pass through this pump, or if that is undesirable upper and lower strainers can be used to prevent oversize material from entering the pump.

For system designers and structural planners, the V Series brings even more features to the table. Because the pump is designed to sit down in a sump, effluent and overflow process streams, which are typically gravity fed, can now be directed into a below-ground sump for collection. No longer will arrangement of pump boxes and above-ground sumps have to be considered with a V Series pump mounted over a below-grade sump or vault.

Mounting the V Series pumps is as simple as four through-bolts on the pump mounting plate. The motor is fully supported on the pump base itself, and can be oriented in either a shaft-up or shaft-down position depending on customer preference and space availability.

Contact Schurco Slurry to find out more about applying these cost-saving workhorse pumps in your plant today.